The digital transformation is not a hype that passes, but rather the consistent adaptation to a changed situation. Even in markets previously considered unassailable, established companies face new competitors that seem to appear out of nowhere.

Company-controlled advertising is no longer the only source of information available to customers. Confidently, ratings are shared on the Net, and forums are used to form an opinion about a product or service’s value and quality.

What is interesting for customers today may be yesterday’s news tomorrow.

Start-ups can implement digital business models with a fraction of the resources required just a few years ago.

Companies with digital services such as Amazon, Netflix, Otto.de, and many others have learned how to deal with the new world and use it as an opportunity. DevOps is a generic term for technologies, methods, values, and principles that help these companies to react quickly and unerringly to change.

How can digital companies’ experience be transferred to companies that use physical machines and production facilities for their value creation?

The goal

„Never touch a running system!” – Once things are running, change as little as possible, is a credo that we better send back to the 20th century and forget. Fast reactions to new requirements are only possible if change becomes the norm.

Like produced and stored unfinished parts, new system functions that are developed but not used are tied up capital that does not generate profit or other added value. Short-term market opportunities may not be used.

DevOps’ goal is the continuous delivery of new software versions (continuous delivery = CD) into production. Several updates daily are conceivable and feasible. Even updates in ongoing production are technically feasible, secure, and beneficial.

CALMS: The foundation for success

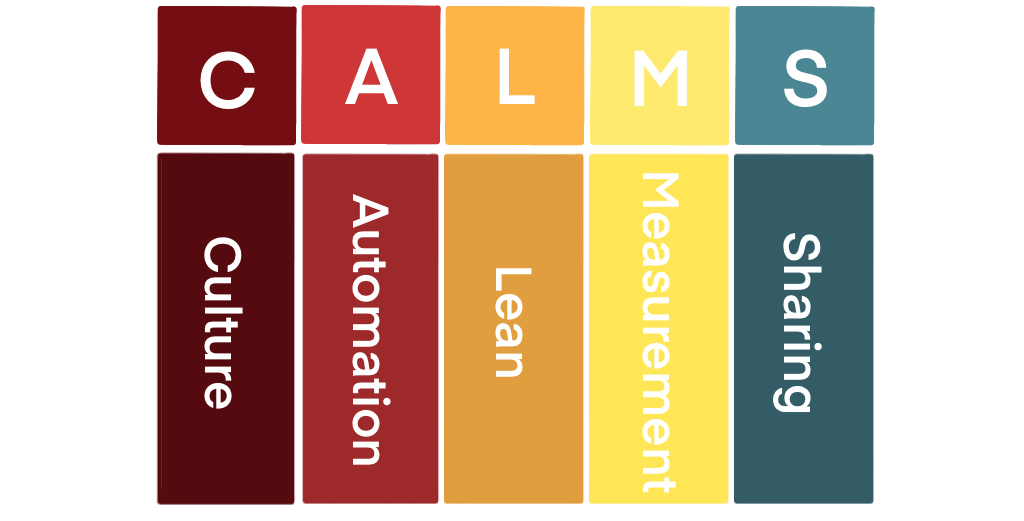

With all the flexibility of software, the constant change of a complex system places high demands on the quality of the implementation. To achieve this, the DevOps community created the acronym CALMS (Figure 1) and described its cornerstones of success.

Many articles and publications on the topic of digital transformation make it clear how important corporate culture is. Digital companies have already discovered that without a suitable culture, DevOps is just theater without effect. The reasons for this are many and varied.

Standardization and automation of complex workflows are essential for reproducible quality. Manual work steps are slow and prone to errors. While Industry 4.0 addressed automation and flexibilization through machines in production, Industrial DevOps focuses on the growing integration of digital systems across departmental and corporate boundaries.

Complex software projects are expensive. However, digital companies have identified long decision-making processes and sometimes unnecessary administrative effort as possible causes.

So the L was inserted to emphasize the role of lean principles and methods in DevOps. Lean originates from the Toyota Production System (TPS) and is intended, among other things, to strengthen value-adding work steps and reduce work that does not deliver value (waste). Interestingly, this is where the circle closes because Lean has long been known and successfully applied in the industry.

Metrics, Measurements, and Monitors

The M for measurements or monitoring forms the basis for the analysis, optimization, and validation of the entire system. The better the measurements, the faster bottlenecks, problems, and on top of it chances and potentials can be identified.

In digital enterprises, dashboards show the current status of the system at all times. For example, if a software update changes a system or servers, network, and other IT infrastructure no longer function correctly, the problem can be quickly identified, analyzed, and (perhaps even automatically) resolved.

In manufacturing companies, machine data helps to identify additionally required maintenance and thus prevent outages (predictive maintenance).

Measurements help to detect and correct errors quickly. Thus, the effects of errors are reduced, and similar errors can be avoided in the future.

Share information

Centrally collected data is available to all participants in real-time. This forms the basis for S, the sharing. Technical systems do not usually change on their own (at least not for the better). This requires the creativity and experience of people who work with the system and contribute their expertise. Teamwork and a common understanding of the requirements and the current situation require transparency and low hurdles to obtain and understand the required information.

Industrial DevOps

Many of the proven DevOps tools and methods help to bring software updates into production routinely. However, the close integration of software and physical machines brings new challenges.

When machines, sensors, and actuators are connected by software, cyber-physical systems are created.

Figure 2 shows how business functions, software development, software operation, and production in the company work together continuously and transparently.

Digital companies have learned to approach challenges holistically. The extension of BizDevOps, i.e., the inclusion of the business functions (Biz) or DevOpsSec, which underlines IT security’s importance, are logical developments. Industrial DevOps now bridges the gap between the virtual world of software and the physical world of machines, sensors, and actuators.

Among other things, knowledge areas such as the Internet of Things (IoT), fog computing, smart manufacturing, and the development and testing of embedded software under the umbrella term Industrial DevOps will be examined in a new light. There are also interesting aspects to the design of production plants and machines. DevOps also brings along topics such as Lean, Agile, Systems Thinking, and of course, Artificial Intelligence as an important tool.

Hardware in “stock”

With new investments, the costs for machines and sensors have decreased in relation to software development spending. The purely physical networking of, e.g., sensors, is now possible without much effort. So why not install more than is currently necessary and use software to gradually improve, expand, and adapt the system to new challenges?

Even machine manufacturers can avoid implementing every conceivable function in their firmware during development and instead build hardware in stock and adapt the software as required.

This allows customers to get new features when they are needed. It’s only a software update that’s required for delivery. Telemetry data can also be refined in this way, helping to improve the machine continuously. The evaluation of telemetry is an additional potential benefit for customers.

There are too few programmers

Do all companies now have to build software departments that employ an army of programmers? Large companies go exactly this way and develop individual software for their core business themselves. Startups also work their way into the market with their own software solutions.

However, when all companies start to build up software departments, suitable applicants become scarce and thus expensive. The effects are already clearly visible. It is expected that the costs of qualified personnel will continue to rise in the coming years. Small and medium-sized companies in particular could then possibly be left behind when it comes to digitalization.

Analysts like Gartner see Low-Code and No-Code programming as a way to counter this trend. Specialists without programming skills are thus able to implement a large part of the daily requirements themselves. In particular, the translation of data formats and connecting system components should be a routine part of daily business.

The necessary software components are supplied by hardware manufacturers or developed by service providers. One platform provides solutions for standard tasks. The development of components is thus simplified and thus faster and cheaper.

Digital sovereignty

When choosing a suitable platform or application, your own digital sovereignty should be the first priority. After all, it is the core business at stake. Over time, extensive systems emerge. The Low-Code/No-Code application is the “glue” that connects the components of the system. Here a dependency on the software provider easily arises, which can become a problem if, for example, company policy or license conditions change.

Especially Medium-sized companies may encounter difficulties in enforcing their own requirements with large manufacturers. Open-source licensing models offer a good alternative to “Do It Yourself” (DIY). The contact with the community and active participation helps to influence the project in the desired direction. This requires effort and commitment, but it pays off quickly.

Digital transformation? Yes, please!

Like DevOps, Industrial DevOps is not the goal, but the way. Companies are required to adapt to the pace of market change. Making mistakes in a controlled manner, and learning from them is just as much a part of this as an unsparingly realistic perception of one’s own company’s internal and external situation. In an increasingly complex world, correct answers are hard to find. What is right for one person can be wrong for another.

The software provides the necessary freedom, creates connections where connections are needed, and can be quickly adapted to new challenges.

Decision-makers need to have long-term goals and not lose sight of them. The path to the destination is not a well-planned highway but rather an expedition into unknown territory. There are surprises and detours, but also opportunities, which only become apparent when a part of the way has already been covered.

Digital companies have already learned to deal with complex systems and challenges and meet them with software.

Industrial DevOps is intended to inspire people to think outside the box and use the power of modern, distributed IT systems in manufacturing companies to create added value through software and to see change as an opportunity.

Links

Digital transformation: online guide to digital business transformation; https://www.i-scoop.eu/digital-transformation/

Russell L. Ackoff; https://en.wikipedia.org/wiki/Russell_L._Ackoff

If Russ Ackoff had given a TED Talk…; https://youtu.be/OqEeIG8aPPk

What is BizDevOps?; https://enterprisersproject.com/article/2019/9/devops-what-is-bizdevops

Applying DevOps and Continuous Delivery to Significant Cyber-Physical Systems; https://itrevolution.com/book/industrial-devops/

Industrial DevOps; https://www.researchgate.net/publication/333062727_Industrial_DevOps

What is Embedded Software?; https://www.pebblebay.com/what-is-embedded-software/

Fog computing: a decentralized approach for IoT clouds; https://www.ionos.com/digitalguide/server/know-how/fog-computing/

Why Smart Manufacturing?; https://spectrum.ieee.org/consumer-electronics/standards/why-smart-manufacturing

Further references

Erfolgreiches Management von Instabilität; Peter Kruse; GABAL Verlag GmbH

Lean Enterprise; Humble, Molesky, O’Reilly; 2014 O’Reilly Media, Inc.